One of the first things any new welder learns is knowing how to properly ground to avoid consumables and ensure quality welds. Most commonly, the welder is grounded using clamps made of copper or brass. To complete the circuit and enable the welder to produce an arc, this is done. So how to ground a MIG welder? This article will teach you the best way to ground your welder.

The importance of grounding when welding

Welding is considered a rather dangerous profession as workers can suffer injuries such as burns and electric shock. When it comes to eliminating electrical shocks, this is where grounding comes in handy and keeps the welder out of harm’s way. Circuit grounding is a fairly common safety practice and this is the main reason to ground your welder. Circuit grounding is one of the basic safety standards that welders must adhere to. It does not automatically eliminate the risk of electric shock, but it greatly reduces the risk.

Besides the safety standards it allows you to maintain, grounding electrical circuits also prevents welders from making low-quality welds. This is because all the current in your welder goes through your grounding clamp. This means that if your connection is not good, the performance of the welder will suffer, resulting in poorer weld quality.

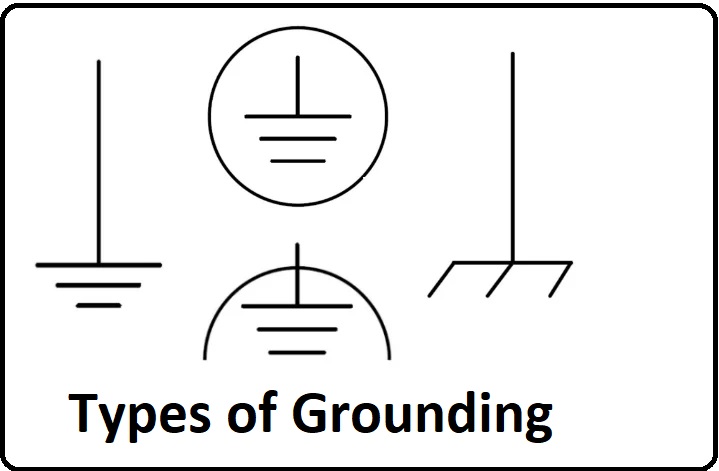

Types of grounding

- Grounding Connectors

Many soldering irons use a grounding setup that incorporates plugging the soft cable into a specific outlet. Although some are permanently wired, this is particularly uncommon. When you connect the device to the ground it keeps both of them at the same power potential and keeps you from getting jerks if you touch both pins on the welder. - Double Insulation

Some welding machines are designed with double insulation. They do not require a grounded conductor because the additional insulation protects you from electric shock. - Grounding Pins in Plugs

Most smaller welders use a plug at the end of the power cord. The machine is automatically grounded when plugged into a power source. - Test Circuits

Use a test circuit that will check if your ground is working correctly. - Workpiece Grounding

A solder circuit consisting entirely of conductive material. This conductive substance is through which the welding current for your project travels. - High-Frequency Grounding

Some machines use high-frequency voltage to start up and stabilize the current. As they approach the welding region, these high-frequency waves tend to migrate away. This indicates that they frequently obstruct radio and television reception and may even harm nearby electronics. - Portable Welding Machines and Vehicle-Mounted

Generators used for remote and mobile welding projects typically provide an auxiliary power supply of 120 to 240 volts. These generators are not connected to an existing electrical system, so it is often not possible to find a convenient built-in method for grounding the machine. For generators, it is recommended that you attach the power source to the truck or trailer. Power must be obtained from an outlet with a cord and plug. They must have a ground pin.

How to ground a MIG welder?

Grounding your welder is as simple as placing your grounding clamp on the workpiece. Ground clamp on clean metal and as close to where you are welding as possible. To ground the welder, you simply connect the circuit by placing a ground clamp on your workpiece. This must have enough conductivity to complete the circuit while also grounding to prevent sparks and electric shock. It’s safe to have a damper at hand, such as wood, in case anything happens and you need to stop the current from flowing through your body. Inside there are many clamps, the ground wire will hook into a lug. There is an internal contact plate on either side of the clamp.

Larger clamps are usually made entirely of conductive metal, with giant springs and molars for extra contact. Squeeze and squeeze it firmly into the ground so that all your traction happens on the clamp and not the cable so it doesn’t pull loose on your ground. If you’re working on a metal bench, simply clip it to a bench or table somewhere clean. Now your cable has become part of the ground, so if you lean on the cable or a desk you may get jolts.

Conclusion

Hopefully, after reading this article, you now have a much clearer idea of what grounding is, the types of grounding and how to ground a MIG welder. Now that you understand the importance of grounding while welding, you can avoid damaging your weld or worse, getting an electric shock while working. Once you’ve mastered the art of grounding and leading the work, you’ll be in a much better position to put in some high-end soldering, and on top of that, you’ll do it in a much safer way. In addition to grounding, you must have the right welding safety equipment for the specific job you face to avoid electric shock, burns, and other hazards.

Read more: