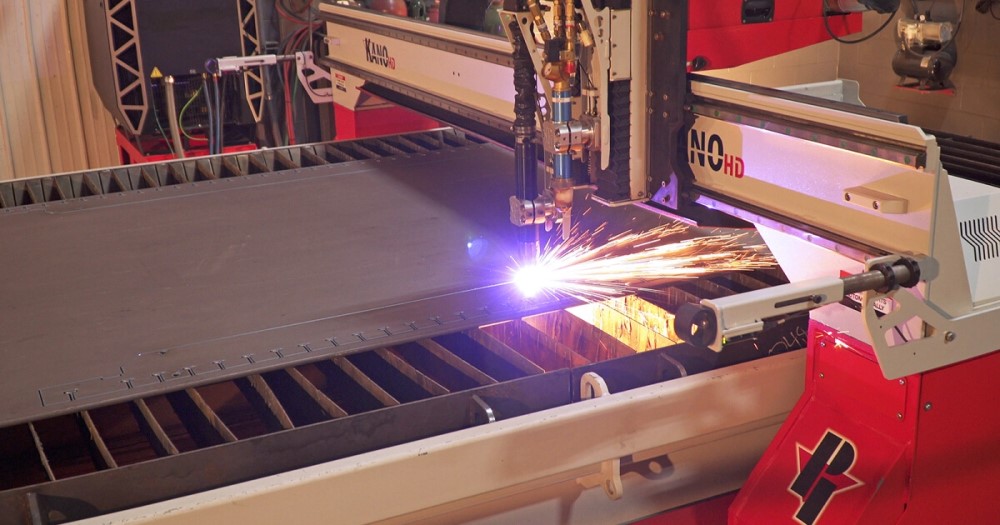

Are you a beginner in CNC Plasma cutting or thinking about buying a CNC Plasma cutting machine? But you still don’t know How to operate CNC Plasma cutting machine? Don’t worry, the welderprofessor will give you some tips and instructions on how to do it right below. Let’s find out together!

Steel and other electricity-conductive metals can be cut by plasma cutting, which is a highly effective and economical method. The plasma cutter first raises the temperature of the compressed air using DC voltage and then ionizes the atoms to produce a pilot arc. The precise cut and superior finish are the consequence of this tiny plasma jet pushing through and melting the metal.

Things to note when operating a CNC Plasma cutting machine

A plasma CNC machine is a metal engraving cutting device that can cut through hard materials like steel, iron, doors, staircases, partitions, etc. in both straight lines and curves. The mechanical sector has advanced significantly because of plasma CNC machines. We must be aware of the following issues to properly run the CNC plasma cutting machine:

For the machine to function properly, the guide rails must be routinely cleaned to remove water and dust. Grease the bearings occasionally, and spray the machine with dust before use. Maintain the plasma cutting source’s cleanliness.

To run the CNC plasma machine, 400 liters of air must flow every minute, the pipe being used must be at least 12 mm in diameter, and the minimum compressed air pressure must be 5.5 bar. To ensure the flow, we can raise the cross-section of the gas pipeline and decrease its length. Flow could not be enough while sharing numerous loads at once. The best approach is to incorporate an accumulator close to the machine.

Use a water and oil separator (add filter) or a screw machine with a water and oil separation system to pass compressed air through before it enters the machine. In the presence of water or oil, the cutting tip is prone to the contamination that prevents ignition. In this situation, remove the cutting tip, clean the electrode, replace it, and turn off the plasma source to clear the mistake before operating.

Preparing to use CNC Plasma cutting machine

Before using the CNC plasma cutting machine, the operator must carefully verify that the torch is straight and parallel to the cutting table. Examine the cutting tips carefully with the electrodes to see whether or not they are still useable so that you can take prompt corrective action. To ensure that the product is of the highest quality and that the cutting tip won’t cause the product to be damaged while cutting, check the type of cutting tip to determine if it is appropriate for the thickness of the cutting material.

You should double ensure that the torch is firmly linked to the rack after thoroughly inspecting the complete cutting machine. You should also examine the overall to see whether the CNC plasma cutting machine has any issues. Avoid the scenario where the torch is placed at the incorrect price, impacting the effectiveness of the cutting line.

Before cutting, make sure the pressurized air line to the machine has enough load and that the input voltage is adequate to prevent disruptions during the cutting process.

When utilizing a handheld CNC plasma cutter, the user must grip the device firmly with both hands to easily maintain the cutting distances of the cutting head with the material face. It is necessary to cut in places where the operator can move easily and yet run the CNC plasma cutting machine.

How to operate CNC Plasma cutting machine

Before pressing the run button, the operator must correctly and completely configure the settings. Material, cutting material thickness, cutting pattern, punching time, cutting speed, etc. are some of the factors that must be properly set. The CNC Plasma cutting machine can be used once all the settings have been made.

It should be pretty easy to notice the cut for a skilled operator. But before cutting, especially for lengthy cuts, it is necessary to perform some review procedures for people who have not used a handheld plasma cutter often. As a result of the practice, the operator will be able to cut more evenly and prevent situations in which they can trip or slip while operating the cutting line, which would compromise the quality of the cut product.

Before beginning to cut on actual products, the operator must test each sort of cutting material. This can help the operator get a sense of how those materials are chopped and help him or her comprehend it.

When you observe sparks shoot back onto the surface of the cutting material when the CNC plasma cutting machine or the portable plasma cutting machine is operating. This demonstrates that you shifted the cutting head too quickly, preventing the electric arc from striking the cutting materials and returning. The machine’s operating speed needs to be slowed down by the operator to overcome this.

Depending on the thickness and complexity of the cut, we must modify the cutting speed for each type of material to produce goods with the most precise and attractive cutting lines.

The result of a thick material cut made using a CNC plasma cutter might not be what you were hoping for. Because it may have an impact on the cutting product, this will make it challenging for beginners to use plasma cutters. Therefore, the strategy, in this case, requires the operator to lower the cutting speed while approaching corners or at the end of the cut.

When utilizing a portable plasma cutter, it is essential to manage the device at a slower pace at the cutting path’s beginning and conclusion so that the machine can entirely remove the material without leaving significant gaps of material. A tiny quantity of plasma cutting slag will frequently be present below the cutting line when cutting materials with a large thickness.

In the event of an abnormality, while the CNC plasma cutting machine is in operation, you should stop using it or push the emergency stop switch, but you should avoid moving the machine or the plate.

Conclusion

Iron, nickel, aluminum, carbon steel, stainless steel, and other metals can all be cut with a plasma cutter. Different sizes and forms are available for plasma cutters. Both large-format CNC plasma cutting tables with robotic arms for precision cutting control and sleek portable plasma cutters used in mobile workshops are available. No of their size, plasma cutting machines all operate under the same general concept and have a very similar structural layout.

Above are our instructions on how to use a CNC plasma cutter and a few notes for you. When using a CNC plasma cutting machine, even those with no prior experience can operate one by following this manual. Our final advice is that you must install strong ventilation devices in the work area of the equipment to remove all the smoke generated during the cutting process of the CNC plasma cutting machine. Good luck!

Maybe you want to know: The best 2 Helmets and 3 ESAB Sentinel A50 Lenses